CARBON STEEL PIPE CARBON SEAMLESS STEEL PIPE CARBON STEEL SEAMLESS PIPE

Kev piav qhia

Seamless Steel Yeeb Nkab yog tsim los ntawm cov khoom siv puag ncig steel 'billet' uas yog rhuab thiab thawb los yog rub hla ib daim ntawv kom txog thaum cov hlau zoo li lub raj hollow.Cov yeeb nkab seamless yog ua tiav rau qhov loj me thiab phab ntsa thickness specifications hauv qhov ntau thiab tsawg los ntawm 1/8 nti mus rau 32 nti OD.Carbon Steel Seamless Pipes / Tubes Cov pa roj carbon steel yog cov hlau uas muaj hlau thiab carbon.Qhov feem pua ntawm cov pa roj carbon nyob rau hauv cov hlau cuam tshuam rau hardness, lub zog ntawm elasticity thiab ductility ntawm carbon steel.Seamless carbon steel yeeb nkab lossis cov khoom steel ingot yog ua los ntawm cov raj capillary los ntawm lub qhov, tom qab ntawd los ntawm kub dov, txias dov los yog txias hu.Seamless carbon steel yeeb nkab hauv Tuam Tshoj txoj kev lag luam steel muaj txoj haujlwm tseem ceeb.Seamless carbon steel yeeb nkab khoom yog ib puag ncig lub raj, yeeb nkab txiav tshuab embryos mus txog kev txiav li 1 m ntawm qhov ntev dawb paug, thiab xa los ntawm conveyor siv rauv cua sov.Billet yog noj rau hauv lub qhov cub cua sov, qhov kub thiab txias yog li 1200 degrees Celsius.Roj yog hydrogen los yog acetylene.Lub qhov cub kub tswj yog qhov teeb meem tseem ceeb.Round raj tuaj tawm mus rau punch los ntawm lub tshuab los ntawm huab cua siab.Feem ntau cov punch ntau yog tapered yob perforation tshuab, lub punch siab ntau lawm efficiency, khoom zoo, loj txoj kab uas hla qhov expansion, tuaj yeem hnav ntau yam hlau.Perforation, round raj tau nyob rau ntawm peb-yob ntoo khaub lig dov, dov los yog extrusion.Squeezed tawm lub raj tom qab sizing.Sizing los ntawm high-speed rotary cone laum qhov rau hauv lub billet los tsim ib lub raj.Yeeb nkab txoj kab uas hla los ntawm sizing zeb los txiav txim qhov ntev ntawm lub laum txoj kab uas hla.Tom qab cov yeeb nkab los ntawm sizing mus rau hauv lub txias ntauwd, txias los ntawm cov dej tsuag, steel tom qab txias, yuav tsum tau straightening.Tom qab siv txoj hlua hlau xa los ntawm kev ntsuas hlau ncaj qha (los yog kev ntsuas siab) rau kev sim sab hauv.Yog tias cov yeeb nkab sab hauv tawg, npuas thiab lwm yam teeb meem yuav raug kuaj pom.Tom qab cov yeeb nkab tab sis kuj dhau los ntawm kev tswj hwm nruj tswj kev xaiv.Steel zoo, siv cov xim pleev xim rau cov zauv, specifications, ntau lawm naj npawb.Los ntawm ib tug crane mus rau hauv lub warehouse.

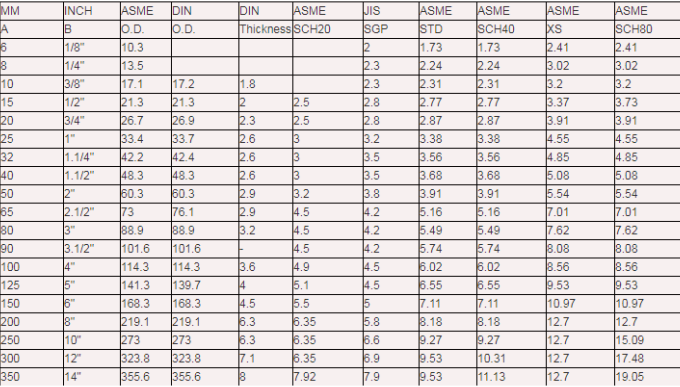

Phab ntsa thickness ntawm seamless yeeb nkab

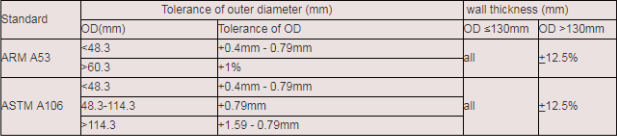

Kev kam rau sab nrauv thiab phab ntsa thickness

Specification

| Txuj | Kev piav qhia |

| ASTM A179 / A179M | Seamless txias kos tsis tshua muaj hlau hlau kub exchanger thiab condenser raj. |

| API 5L | Kab yeeb. |

| ASTM A53M 1 | Dub & Zinc Coated Welded thiab Seamless Steel Yeeb Nkab. |

| ASTM A106M 3 | Seamless carbon steel yeeb nkab rau kev pabcuam kub. |

| ASTM A105M 1 | Carbon steel forgings rau kev siv piping. |

| ASTM A234M 1 | Piping fittings ntawm wrought carbon steel thiab alloy steel rau nruab nrab thiab kub kev pab cuam. |

Txuj

| Txuj | Hom yeeb nkab | Chav kawm | Qib |

| API SPEC 5L TS EN ISO 3183 | SMLS | PLS 1 | L245B, L290 X42, L320 X46, L360 X52, L390 X56, L415 X60, L450 X65, L485 X70 |

| PLS 2 | L245N BN, L290N X42N, L320N X46N, L360N X52N, L390N X56N, L415N X60N, L360Q X52Q, L390Q X56Q, L415Q X60Q, L485Q X70Q | ||

| PLS2 Sour Ib puag ncig | L245NS, L290NS X42NS, L320NS X46NS L360NS X52NS, L390NS X56NS, L415NS X60NS, L360QS X52QS, L390QS X56QS, L415QS X60QS L485QS X70QS | ||

| WELD | PLS 1 | L245B, L290 X42, L320 X46, L360 X52 L390 X56, L415 X60, L450 X65, L485 X70 | |

| PLS 2 | L245M BM, L290M X42M, L320M X46M, L360M X52M, L390M X56M, L415M X60M, L450M X65M, L485M X70M, L555M X80M, |

| Txuj | Qib |

| ASTM A53 M | A, B |

| ASTM A 106 M | A, B, C |

| TIAB SA 3454 | SIB 370, STPG 410 |

| TIAB SA 3455 | STPG370, STPG410, STPG480 |

| TIAB SA 3456 | STPG370, STPG410, STPG480 |

Qib: Chemical Composition (%):

| Txuj | Qib | C | Si | Mn | P | S | Ni | Cr | Cu | Mo | V |

| ASTMA 53M ua | A | ≤ 0.25 | - | ≤ 0.95 | ≤ 0.05 | ≤ 0.045 | ≤ 0.40 | ≤ 0.40 | ≤ 0.40 | ≤ 0.15 | ≤ 0.08 |

| B | ≤ 0.30 | - | ≤ 1.20 | ≤ 0.05 | ≤ 0.045 | ≤ 0.40 | ≤ 0.40 | ≤ 0.40 | ≤ 0.15 | ≤ 0.08 | |

| ASTM A 106 M | A | ≤ 0.25 | ≥0.10 | 0.27-0.93 Nws | ≤ 0.035 | ≤ 0.035 | ≤ 0.40 | ≤ 0.40 | ≤ 0.40 | ≤ 0.15 | ≤ 0.08 |

| B | ≤ 0.30 | ≥0.10 | 0.29-1.06 Nws | ≤ 0.035 | ≤ 0.035 | ≤ 0.40 | ≤ 0.40 | ≤ 0.40 | ≤ 0.15 | ≤ 0.08 | |

| C | ≤ 0.35 | ≥0.10 | 0.29-1.06 Nws | ≤ 0.035 | ≤ 0.035 | ≤ 0.40 | ≤ 0.40 | ≤ 0.40 | ≤ 0.15 | ≤ 0.08 | |

| TIAB SA 3454 | TIAB SA 370 | ≤ 0.25 | ≤ 0.35 | 0.30-0.90 Nws | ≤ 0.040 | ≤ 0.040 | - | - | - | - | - |

| TIAB SA 410 | ≤ 0.30 | ≤ 0.35 | 0.30-1.00 Nws | ≤ 0.040 | ≤ 0.040 | - | - | - | - | - | |

| TIAB SA 3455 | TIAB SA 370 | ≤ 0.25 | 0.10-0.35 dr hab | 0.30-1.10 Nws | ≤ 0.035 | ≤ 0.035 | - | - | - | - | - |

| TIAB SA 410 | ≤ 0.30 | 0.10-0.35 dr hab | 0.30-1.40 Nws | ≤ 0.035 | ≤ 0.035 | - | - | - | - | - | |

| TIAB SA 480 | ≤ 0.33 | 0.10-0.35 dr hab | 0.30-1.50 Nws | ≤ 0.035 | ≤ 0.035 | - | - | - | - | - | |

| TIAB SA 3456 | TIAB SA 370 | ≤ 0.25 | 0.10-0.35 dr hab | 0.30-0.90 Nws | ≤ 0.035 | ≤ 0.035 | - | - | - | - | - |

| TIAB SA 410 | ≤ 0.30 | 0.10-0.35 dr hab | 0.30-1.00 Nws | ≤ 0.035 | ≤ 0.035 | - | - | - | - | - | |

| TIAB SA 480 | ≤ 0.33 | 0.10-0.35 dr hab | 0.30-1.00 Nws | ≤ 0.035 | ≤ 0.035 | - | - | - | - | - |

Painting & Txheej

Kev kho deg ntawm cov yeeb nkab steel: txhawm rau txhim kho lub neej kev pab cuam ntawm cov kav dej, kev kho deg feem ntau yog ua los pab txhawb kev sib xyaw ua ke ntawm cov yeeb nkab steel thiab cov txheej txheem tiv thaiv corrosion.Cov txheej txheem ua haujlwm feem ntau yog: tu, cuab yeej derusting, pickling, tua blasting derusting. plaub pawg.

1.Tshuaj Roj, plua plav, roj nplua nyeem, organic teeb meem adhered rau saum npoo ntawm cov yeeb nkab steel, feem ntau yog siv cov kuab tshuaj, emulsion los ntxuav qhov chaw.Txawm li cas los xij, cov xeb, oxide daim tawv nqaij thiab vuam slag ntawm cov yeeb nkab steel tsis tuaj yeem raug tshem tawm, yog li lwm txoj kev kho mob yuav tsum tau.Tool xeb tshem tawm steel yeeb nkab nto oxide, xeb, vuam slag, tuaj yeem siv steel hlau txhuam los ntxuav thiab txhuam qhov chaw kho.

2.Tool derusting tuaj yeem muab faib ua phau ntawv thiab lub zog, phau ntawv cuab yeej derusting tuaj yeem ncav cuag Sa 2 qib, lub cuab yeej hluav taws xob derusting tuaj yeem ncav cuag Sa3 qib. cov xeb nrog kev pab ntawm cov cuab yeej, yog li peb yuav tsum nrhiav lwm txoj hauv kev.

3.Pickling Common pickling txoj kev muaj xws li chemistry thiab electrolysis.Tab sis tsuas yog cov tshuaj pickling yog siv rau pipeline corrosion tiv thaiv.Chemical pickling yuav ua tau ib tug tej yam kev huv si thiab roughness nyob rau saum npoo ntawm cov yeeb nkab steel, uas yog yooj yim rau tom ntej thauj tog rau nkoj kab. txhaj tshuaj (xuab zeb) tom qab reprocessing.

4.Shot blasting rau xeb tshem tawm.By siab zog lub cev muaj zog tsav lub high-speed rotating hniav, steel grit, steel txhaj, ntu, minerals thiab lwm yam abrasive hlau nyob rau hauv qhov kev txiav txim ntawm centrifugal quab yuam ntawm steel yeeb nkab nto tshuaj tsuag thiab loj ejection, kom huv si tshem tawm. xeb, oxides thiab av ntawm ib sab tes, ntawm qhov tod tes, cov yeeb nkab steel nyob rau hauv qhov kev txiav txim ntawm abrasive hnyav cuam tshuam thiab kev sib txhuam quab yuam, kom ua tiav qhov yuav tsum tau ua kom zoo li qub. cev derust.Feem ntau, txhaj tshuaj blasting thiab derusting yog tsuas yog siv rau sab hauv kev kho mob ntawm cov yeeb nkab steel, thiab tua blasting thiab derusting yog tsuas yog siv rau sab nrauv kho cov yeeb nkab steel.

Packing & Loading

Txau xim

Waterproof ntim